Njengoko imakethi ye-micro-pitch iqhubeka nokufudumala, i-4K kunye ne-8K ephezulu-definition iye ngokuthe ngcembe ibe ngumgangatho omtsha wokuboniswa kwe-LED, kwaye imfuno yemarike ye-high-definition displays iyanda.COB , ngubani onokufumana ukuqatshelwa kwemarike kwindlela ye-micro-pitch display? Ezi teknoloji zokupakisha zineemfanelo zazo, kodwa ixesha le-micro-pitch lifikile. Njengomda wexesha le-micro-spacing, i-COB yamkelwe ngokubanzi yintengiso. Ngokukhula okubalulekileyo kweUmboniso we-LED we-P0.9 kwimarike kulo nyaka, i-COB iye yaba yi-protagonist yenkcazo ye-LED yangaphakathi. Kwixesha elizayo elibonakalayo, njengoko isithuba sisiba sincinci Ukuhla, i-COB iya kuba lelona cala liphambili lemveliso yentengiso.

Ngenkqubela phambili eqhubekayo yetekhnoloji yeCOB, kulo nyakaUmboniso we-LED we-micro-pitch , i-cathode eqhelekileyo, i-flip-chip, ukuhanjiswa kobuninzi kunye namanye amagama abe yingqwalasela yeendaba ngamaxesha amaninzi, zeziphi ezi teknoloji? Limisela njani ikamva le-COB yetekhnoloji encinci ye-pitch ukuya?

I-teknoloji ye-cathode eqhelekileyo - ukugcinwa kwamandla, ukuxinana okuphezulu kunye nokusetyenziswa kwamandla aphantsi

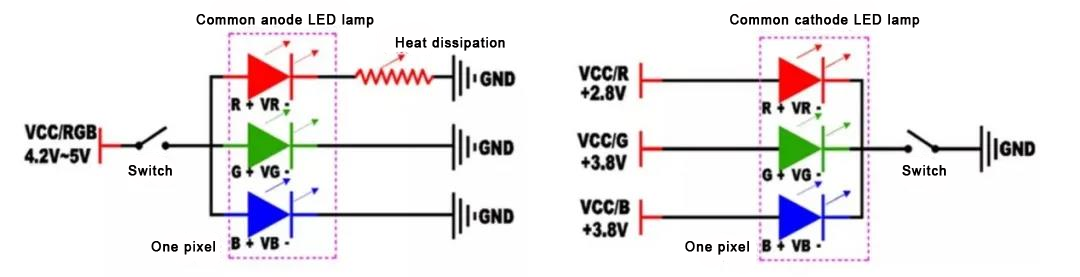

Umboniso we-LED oqhelekileyo wamkela i-anode eqhelekileyo (i-postitive pole) imo yokubonelela umbane, ukuhamba kwangoku kwibhodi ye-PCB ukuya kwiintsimbi zesibane, kunye neentsimbi zesibane eziqhelekileyo ze-anode kunye nomqhubi ohambelanayo we-IC kunye ne-RGB izibane zesibane zisetyenziselwa ukunikezelwa kombane odibeneyo. I-cathode eqhelekileyo ibhekisela kwi-cathode eqhelekileyo (i-pali engafanelekanga) indlela yonikezelo lwamandla, usebenzisa amaso aqhelekileyo wesibane se-cathode kunye neskimu esikhethekileyo somqhubi we-IC, i-R kunye ne-GB inikwe amandla ngokwahlukeneyo, kwaye okwangoku idlula ngamaso wesibane kwaye emva koko iya kwi-IC. cathode. Emva kokusebenzisa i-cathode eqhelekileyo, sinokunikezela ngokuthe ngqo kwii-voltages ezahlukeneyo ngokweemfuno ezahlukeneyo ze-diode yombane, ngoko akukho mfuneko yokuqwalasela i-resistor ye-voltage divider ukunciphisa ukusetyenziswa kwamandla kule nxalenye, kodwa ukukhanya kunye nokubonisa ukukhanya. iziphumo azichatshazelwa, kwaye ukonga amandla kunyuswe ngama-25% ~ 40%.

Uthini umahluko phakathi koyilo lwe-drive cathode kunye ne-anode eqhelekileyo?

Okokuqala, indlela yokuqhuba iyahluka. Ukuqhuba i-cathode eqhelekileyo kuthetha ukuba i-current yokuqala idlula kwi-bead yesibane kwaye emva koko iye kwi-electrode engafanelekanga ye-IC, ukwenzela ukuba i-voltage yangaphambili ihla ibe yincinci kwaye i-on-resistance ibe yincinci. I-anode drive eqhelekileyo kukuba i-current iphuma kwibhodi ye-PCB ukuya kwi-bead yesibane, enika amandla kwi-chip ngokufanayo, kwaye ukuhla kwamandla ombane ohamba phambili wesekethe kuba mkhulu.

Okwesibini, amandla ombane ombane ahlukeneyo, i-cathode drive eqhelekileyo, i-voltage ye-chip ebomvu i malunga ne-2.8V, kunye nombane we-blue and green chips malunga ne-3.8V. Olu hlobo lonikezelo lwamandla lunokufezekisa unikezelo lwamandla oluchanekileyo kunye nokusetyenziswa kwamandla amancinci, kunye nobushushu obuveliswa ngumboniso we-LED ngexesha lomsebenzi. Kwakhona iphantsi ngokwentelekiso. I-anode drive eqhelekileyo, phantsi kwemeko yangoku rhoqo, ukuphakama kombane, amandla aphezulu, kunye nomlinganiselo omkhulu wokusetyenziswa kwamandla. Ngexesha elifanayo, i-chip ebomvu idinga i-voltage ephantsi kune-blue and green chips, ngoko ke kuyimfuneko ukwandisa umhluli wokuchasana Ngaphantsi koxinzelelo, umboniso okhokelwayo uya kuzisa ukushisa okukhulu ngexesha lomsebenzi.

I-teknoloji ye-SRYLED - ilitye eliphambili lokuphuhliswa kweUmboniso we-LED we-micro-pitch

Izibonelelo zetekhnoloji ye-COB ngokwayo ibe yinto ekugxilwe kuyo kwintengiso, kwaye i-SRYLED COB inyuse itekhnoloji ye-COB kwindawo entsha. I-COB ngokwayo iyitekhnoloji yokupakisha enezibane ezininzi ezidityanisiweyo ezifakela ngokuthe ngqo i-chip ekhupha ukukhanya kwibhodi yePCB. Inkqubo edinayo yokunyusa umphezulu ayifakwanga, kwaye akukho nyawo lwesolder yesibiyeli. I-chip ye-LED kunye nocingo lwe-soldering ye-pixel nganye ifakwe ngokuqinileyo kwaye ifakwe ngokuqinileyo kwi-colloid nge-epoxy resin, ngaphandle kwezinto eziveziweyo. Ukukhusela, kunokusombulula ingxaki yomonakalo kwiipikseli ezibangelwa yimiba yangaphandle. I-SRYLED COB inokunyusa kakhulu ukuxinana kwangoku, ukuphucula ukuzinza kunye nokusebenza kakuhle kokukhanya kwezibane zesibane, kunye nesakhiwo se-SRYL sinokuhlangabezana neemfuno ezinjalo. , Ukuthembeka okuphezulu, kunye neenzuzo zemithombo yokukhanya engabonakaliyo yokukhanya ukuqhubela phambili ukuphucula ukuthembeka, ukwenza lula iinkqubo zokuvelisa, kunye nokufezekisa iziphumo ezingcono zokubonisa, ezinokufikelela kwi-chip-level spacing kunye nokufikelela kwinqanaba le-Micro LED.

Ziziphi iingenelo eziziswa yiCOB?

I-COB iwela imida yetekhnoloji yokupakisha kwaye yenza i-pitch ibe ncinci. Siye sasungula iimveliso ezine-pitch ye-0.6mm ukuhlangabezana neemfuno ze-high-definition ye-8K ye-LED yesiboniso. Kule mihla, isetyenziswa kakhulu kumaziko omyalelo ahlukeneyo, amaziko edatha, amaziko e-studio, amaziko enkomfa, amaziko orhwebo, iithiyetha zasekhaya, njl. ubukrelekrele, kunye nesantya esikhawulezileyo solwakhiwo lolwazi lwesizwe kunye nenguqu yolwazi lwasezidolophini, indawo yentengiso yokubonisa urhwebo iya kuqhubeka ukuphuhla. , imidiya yokuzonwabisa kunye nemimandla yokhuseleko, amathemba emarike akhanya kakhulu. Kwixesha elizayo, iimveliso zokubonisa ziya kuqhubeka ziphuhlisa ukuya kwiipatshi ezincinci.

Ixesha lokuposa: Mar-07-2022